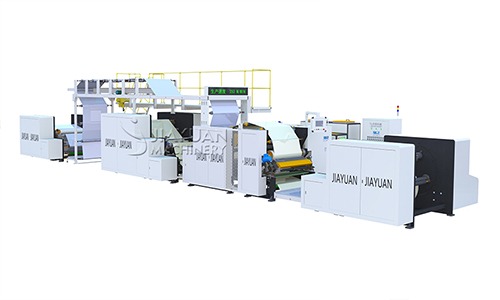

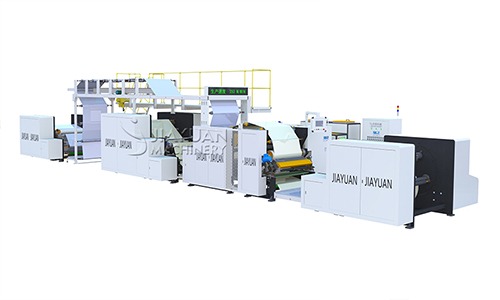

Processes Involved in Repairing Non Scratch Coating Machine

Introduction

Repairing a non-scratch coating machine requires a series of complex processes to ensure its functionality and efficiency. By following these processes diligently, you can effectively restore the machine to its optimal state

Inspection and Diagnosis

+ Initial Inspection: The first step in repairing a non-scratch coating machine is to conduct a thorough inspection to identify the root cause of the issue

+ Visual Examination: Check for any visible damages or malfunctions on the machine&39;s surface

+ Diagnostic Testing: Use specialized tools to diagnose the specific problem with the coating machine

Disassembly and Component Replacement

+ Disassembly: Carefully dismantle the non-scratch coating machine to access the internal components

+ Remove Faulty Parts: Identify and replace any damaged or worn-out parts with new ones

+ Cleaning: Ensure that all components are thoroughly cleaned before reassembly

Reassembly and Calibration

+ Reassembly: Put the machine back together, making sure that all parts are properly aligned and secured

+ Calibration: Adjust the settings and parameters of the machine to ensure smooth operation

+ Testing: Conduct a test run to check the functionality of the repair work

Final Inspection and Quality Assurance

+ Final Inspection: Perform a final inspection to verify that the non-scratch coating machine is functioning correctly

+ Quality Assurance: Ensure that the repaired machine meets the required standards for performance and durability

Conclusion

In conclusion, repairing a non-scratch coating machine involves a series of meticulous processes that require attention to detail and precision. By following these steps diligently, you can effectively restore the machine to its optimal state and prolong its lifespan.

HOT LINE: 086-577-65159218

HOT LINE: 086-577-65159218